Predictive maintenance complements and enhances your traditional preventive maintenance procedures with real-time monitoring, machine learning, data analysis, and prediction of unexpected machine behavior with the goal of preventing problems before they occur.

A predictive maintenance IoT platform provides your organization with real-time insights into the health of its equipment.

- Identifying potential machine failures so preventive maintenance is performed and expensive and unscheduled disruptions avoided

- Extending service intervals and optimizing service routes

- Maximize systematic knowledge by analyzing all data from all devices to improve the design of products and services

Implementing and maintaining an effective IoT predictive maintenance solution can be expensive and difficult as it requires expertise in hardware design, communication technologies, security from remote devices to the cloud, and more. Specific implementation challenges include:

- Accurately collecting and processing potentially large amounts of noisy, real-time operational data

- Operate in remote, inaccessible, and potentially harsh environments with poor communications coverage and lack of wired power

- Robust cybersecurity and preventing physical tampering to ensure the integrity of the data and system

The Electric Imp Platform includes all the components for implementing IoT connectivity for predictive maintenance quickly and seamlessly, including lifecycle management and the ability to scale to millions of devices. In particular, it provides the following key attributes for predictive maintenance:

- Custom business logic to process operational data — specific to situation and equipment monitored — to extract relevant and actionable information

- Robust hardware with advanced power management to maximize battery life

- Comprehensive device-to-cloud security, including tamper-resistant hardware, UL 2900-2-2 Cybersecurity certified

The Electric Imp Platform allows you to maximize the lifetime of your equipment and realize a lower TCO by reducing the cost-to-serve and eliminating truck rolls.

Petasense Vibration Mote

Petasense delivers learning sensors for predictive maintenance that allow customers to remotely monitor the health of their critical machines with Industrial IoT technology.

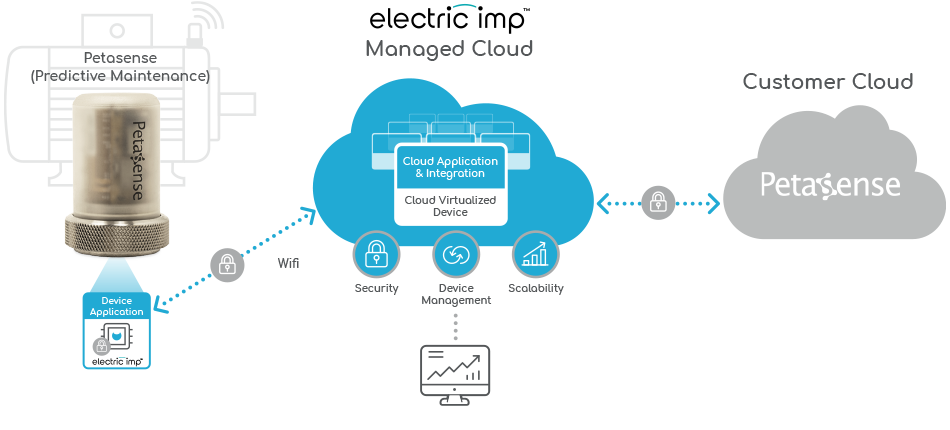

Rather than spend time building sufficient inhouse expertise in embedded hardware, software, and security, Petasense selected the Electric Imp Platform to accelerate the time-to-market of their end-to-end solution for predictive maintenance.

The Petasense solution is comprised of a rugged and battery-powered wireless vibration sensor (the Mote), cloud analysis software, and sophisticated machine learning analytics. The Mote leverages the power and efficiency of the Electric Imp device platform to collect and process vibration data and maximize battery life. This makes it ideal for retrofitting hard to access equipment and significantly reduces maintenance cycles and labor costs for the overall solution.